GLOBAL GASKET MANUFACTURER

AND SEALING SOLUTIONS IN SPAIN

GLOBAL GASKET MANUFACTURER AND SEALING SOLUTIONS IN SPAIN

About Us

FLEXITALLIC IS THE MARKET LEADER IN THE MANUFACTURE AND SUPPLY OF STATIC SEALING SOLUTIONS, DELIVERING HIGH QUALITY INDUSTRIAL GASKETS TO OUR SPANISH PARTNERS.

The Flexitallic Group is committed to its mission of “Making the world safer and cleaner through engineered sealing solutions”. Since the early days, we have been driven by the industry’s need for safe, effective sealing solutions for increasingly demanding applications.

We strive to achieve our mission by providing best-in-class sealing solutions, which allow our Spanish partners to operate their plants, complete projects, and start up from turnarounds safely and efficiently.

We channel the quality, innovation and experience of operating in diverse global markets to support Spanish industry while achieving our corporate goal, which is to provide the components required to achieve zero leaks on start-up and throughout the operating cycle.

Our industrial experience in Spain includes oil and gas, chemical and petrochemical sectors, power generation, solar and nuclear power plants and all other industry that requires high quality gaskets and sealing materials.

Products – Overview

Flexitallic remains at the forefront of developing sealing solutions for industries across the world. Available in Spain, Flexitallic offers a wide range of high quality standard gaskets and customised sealing solutions that allow customers to operate their plants, complete projects and start up from shutdowns safely and efficiently. These products include:

- Novus™ Compressed Fibre Sheet Materials

- Novus™ Graphite Sheet Materials

- Uniflon™ and Sigma® PTFE Sheets/Gaskets

- Spiral Wound Gaskets

- Kammprofile Gaskets

- Ring Type Joint Gaskets

- Thermiculite® – High Temperature Gasket Material

- Change™ Gasket – Heat Exchanger Gasket

- Seals/gaskets for high pressure, high temperature applications

- Seals/gaskets for heat exchangers, thermal cycling

- Seals/gaskets for chemical service

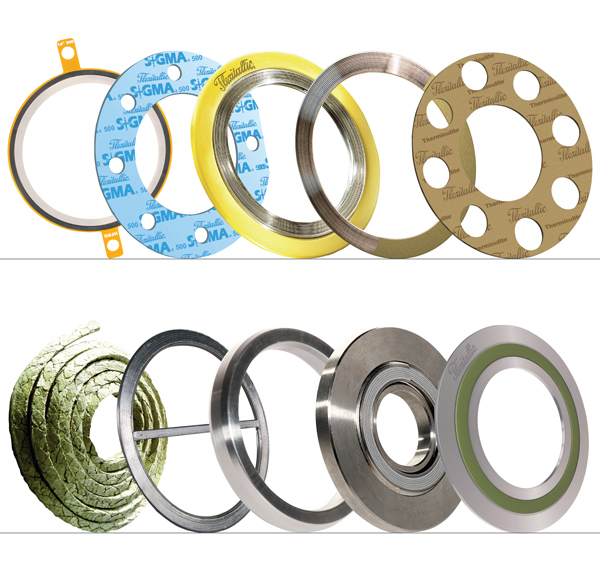

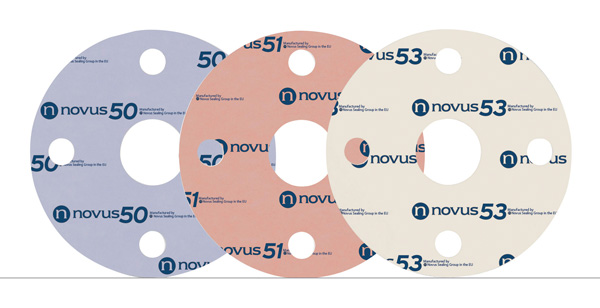

Novus™ Sheet Materials

The Novus™ range of compressed fibre jointing is designed for a wide range of industrial and original equipment applications where sealing performance and reliability is essential.

Based on high performance reinforcing fibres blended with elastomeric binders, the Novus™ materials offer outstanding performance in the most demanding of applications.

Jointing can be supplied as sheet or as cut gasket.

- Sheet Jointing Materials

- Soft Cut Gaskets

- Gasket Materials – General Service

- Gasket/Seals for chemical, pharmaceutical, food

- Gasket/Seals for oils, solvents, gases, steam, diluted acids and alkalis

Novus™ 34

Novus™ 34 is a superior performance universal compressed sheet material with excellent mechanical properties. It is suitable for many applications including oils, solvents, high pressure steam and gases including oxygen.

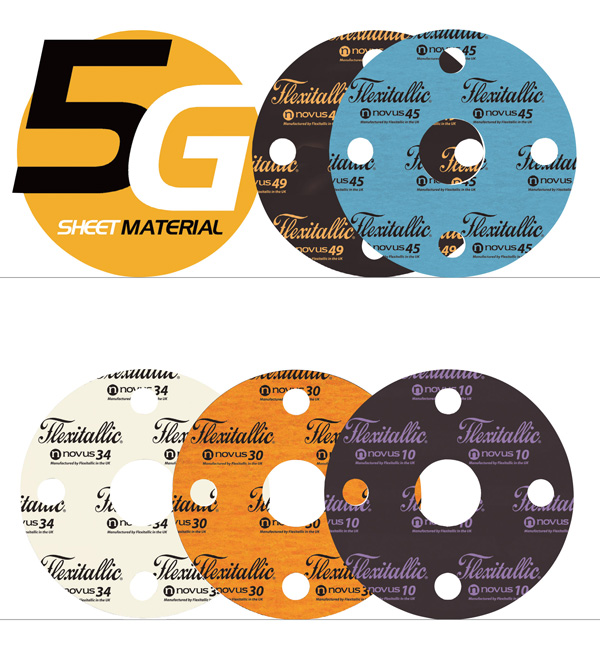

Novus™ Graphite Sheet Materials

The Novus™ range of exfoliated graphite products are designed for demanding, higher temperature applications typical of the petrochemical and refining industries. Manufactured from high purity exfoliated graphite, the product is available with a variety of metallic inserts.

- Graphite Sheet Material

- Tanged Graphite Gasket Sheet

- Tanged Metal Reinforced Graphite Gasket

- Cut Gaskets

- Graphite Gasket/Seals for steam service

- Graphite Gasket/Seals for chemical service

- Graphite Gasket/Seals for high temperatures

Novus™ TI

Novus™ TI is a graphite laminate product reinforced with an insertion of tanged 0.10mm thick 316 stainless steel. No adhesive is required to bond the

graphite layers to the tanged insert resulting in a sturdy gasket material with excellent mechanical strength.

Novus™ Uniflon™ (PTFE) Materials

Novus™ Uniflon™ is a comprehensive range of modified PTFE sealing products designed for applications where chemical resistance is paramount or where food safety is a requirement.

The materials represent the latest generation of filled biaxially orientated PTFE sealing material combining outstanding chemical resistance with excellent sealing performance.

- PTFE Gasket/Seals

- PTFE Sheet Gasket Material

- Cut Gaskets

- Gasket/Seals for chemical, pharmaceutical, food

- Gasket/Seals for standard or irregular flanges

Uniflon™ 50

Novus™ Uniflon 50 is a superior performance biaxially orientated PTFE sheet sealing material with highly conformable properties, ideally suited to both standard and irregular flanges. Novus™ Uniflon 50 is specifically designed for use in low bolt loaded irregular flanges. Typical flanges include glass lined, ceramic plastic coated or uneven/badly distorted flanges. It is suitable for sealing all chemicals across the whole pH range, except molten alkali metals, fluorine or hydrogen fluoride.

Uniflon™ 51

Novus™ Uniflon 51 is a superior performance biaxially orientated PTFE sheet material with a silica filler. A general purpose grade for sealing applications across the whole pH range. It is particularly suitable for use with strong acids (except hydrofluoric acid) and alkalis. Other applications include solvents, fuels, water, steam, and chlorine.

Uniflon™ 53

Novus™ Uniflon 53 is a high performance biaxially orientated PTFE sheet material with barium sulphate filler. A general purpose grade for sealing

applications across the whole pH range. It is suitable for use with hydrofluoric acid, but not pure liquid hydrogen fluoride. It can also be used with alkalis, solvents, fuels, water, steam and chlorine.

Sigma® (PTFE)

Utilising a unique manufacturing process exclusive to Flexitallic, SIGMA® represents the latest generation of multidirectional PTFE materials, which offer very high chemical resistance in processes ranging from cryogenic temperatures to 260°C.

All SIGMA® materials and PTFE filled seals/gaskets are FDA compliant, making them ideal for use in industries where product contamination is of concern.

- FDA compliant seals/gaskets

- Gasket/Seals for chemical, pharmaceutical, food

- Gasket/Seals for cryogenic applications

- Reactor Seals/Gaskets

- Teflon Seals/Gaskets

SIGMA® 511

SIGMA® 511 is a high performance biaxially orientated sheet sealing material containing PTFE with silica filler.

SIGMA® 511 is suitable for sealing most chemicals across the whole pH range

(0-14) with the exception of molten alkali metals, fluorine gas, hydrogen fluoride or materials which may generate these. Sigma® 511 is particularly suitable for use in applications involving strong acids.

Thermiculite®

Process temperatures are rising and operators are looking to extend maintenance intervals. This requires gasket/sealing materials suitable for high temperature applications up to 1000°C which offer safe, long term reliability.

To address these issues, Flexitallic developed a material which has the same gasket sealing characteristics of graphite but the thermal resistance of mica – Thermiculite® high temperature gasket materials.

Suitable for use in critical sealing applications, Thermiculite® has a proven track record in refining, FCCU, fertilizer, nitric acid, ethylene, ammonia production, energy/power, nuclear, mining, petrochemical, marine and OEM applications, and is available as a gasket sheet, spiral wound gasket, kammprofile gasket, Change™ gasket and valve stem packing.

- High temperature gaskets/seals

- Fire-safe gasket/seals (API 6FB)

- Seals for high temperature packings/valves

- Gasket materials for Fuel Cell SOFC

- Gasket/Seals for Fertilizer production

- Cryogenic gasket/seal applications

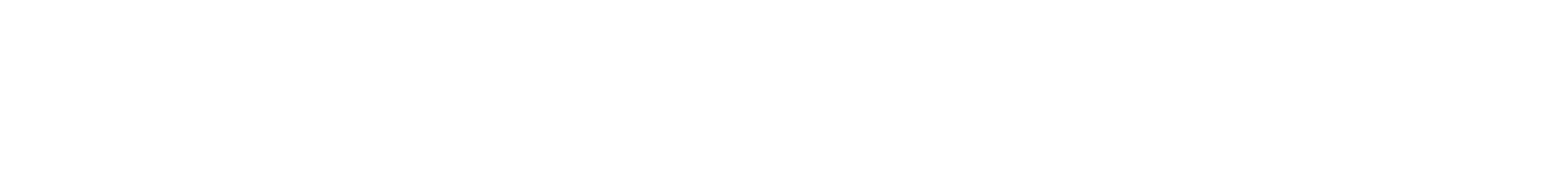

Semi-Metallic Gaskets

Semi-Metallic are composite gaskets which consist of both metallic and non-metallic components.

The metal provides the strength and resilience of the gasket and the non-metallic components provides the conformable sealing material.

These gaskets are suitable for low and high pressure and high temperature applications and include Spiral Wound Gaskets and Flexpro™ Kammprofile Gaskets.

- Spiral Wound Gaskets:

Filler Materials: Graphite, Thermiculite®, PTFE, Corriculite™ - Kammprofile Gaskets

- General purpose gasket

- Gaskets for low/high pressure

- Gaskets for heat exchangers

- Gaskets for high temperature

- Gaskets with inner or outer ring

- Custom shape gaskets

Metallic Gaskets

Metallic Gaskets can be fabricated in a variety of shapes and sizes and are recommended for use in high pressure and high temperature applications.

Gasket types include Ring Type Joint (RTJ), which were initially developed for use in the upstream petroleum industry and are also commonly used on valves and pipework assemblies, and high pressure vessels.

Lens Rings gaskets to DIN 2696 and non-standard are also available.

- Ring Type Joints (RTJ’s)

Style R, Style RX, Style BX - Lens Rings

- Gaskets for high pressure applications and vessels

- Gaskets for offshore and subsea applications

- API 6A Gaskets

- API 17D Gaskets

Change™ Gasket

Due to the cyclical nature of temperature ranges handled by shell and tube heat exchangers, Change™ was originally developed by Flexitallic as a heat exchanger gasket, in response to customers’ long-term sealing problems.

Proven to outperform all other gaskets, Change™ has high recovery properties, without comprising tightness, which is essential in high temperature, thermal cycle applications.

Other typical Change™ applications include boiler manhole gaskets, damaged flanges, reactor seals (FCC, coker, hydrogenation, ethylene/fertilizer production).

- Gasket/Seal for Heat Exchangers

- Fire-safe gasket/seals (API 6FB)

- Gasket/Seals for thermal expansion/thermal cycling

- Gasket/Seals for low surface pressure

- Gasket/Seals for renewable energy

Contact Us:

Juan Luis García Pinelas – Sales Manager, Spain

Tel.: +34 680 535 177

Email: jlgarcia@flexitallic.eu